Core Processes and Applications

• Process Overview: First, a physical object is scanned using a 3D scanner to obtain a massive amount of surface data points, forming a point cloud.

This data is then processed using reverse engineering software to construct a precise 3D model (i.e., reverse modeling).

Finally, this digital model can be used for 3D printing to create a new physical object.

• Cultural Relic Restoration and Reproduction: Damaged cultural relics are scanned and virtually restored and fully modeled on a computer.

3D printing technology is then used to create replicas, preserving the originals while making them accessible to a wider audience.

• Industrial Part Reproduction and Improvement: For old parts without original drawings, scanning and reverse engineering can be used to recreate their 3D models for replica production or optimized design.

• Personalization: Scanning a specific body part, such as a foot, hand, or head, provides accurate data for customized footwear, prosthetics, glasses, helmets, and more.

• Film, TV, and game props: Scan actors' faces to create high-precision masks or digital doubles;

Scan real-world scenes for game modeling, greatly enhancing realism.

High-Precision 3D Scanning Data Processing: Technical Specifications, Common Issues, Storage Conditions, and Product Advantages

High-precision 3D scanning data processing is a transformative technology that enables industries to create accurate digital representations of physical objects. By capturing the geometry of an object with a 3D scanner and processing the data, businesses can perform detailed reverse engineering, product development, and prototyping. The ability to convert physical objects into precise digital models is critical in sectors such as aerospace, automotive, medical devices, and consumer electronics, where accuracy and speed are essential.

This article will explore the technical specifications, common issues, storage conditions, and product advantages of high-precision 3D scanning data processing. By understanding these aspects, businesses can make more informed decisions about implementing this technology to improve their product development processes.

When investing in 3D scanning systems, understanding the technical specifications is critical to ensuring the system will meet the needs of the application. High-precision 3D scanning systems vary in terms of resolution, scanning range, and the types of objects they can scan. Below is a breakdown of key technical specifications:

Resolution: The resolution of a 3D scanner defines how finely it captures the details of an object. High-resolution scanners can capture finer details, which is essential for creating accurate models of complex geometries. For example, resolution can range from 0.01 mm to 0.1 mm, depending on the scanner type.

Accuracy: The accuracy of a scanner refers to how closely the scanned model represents the actual physical object. This is usually defined in terms of absolute accuracy, which can range from ±0.05 mm to ±0.2 mm, depending on the system and conditions.

Short-Range Scanners: Ideal for capturing highly detailed, small objects (e.g., components, parts, or prototypes) at a very fine scale.

Long-Range Scanners: Suitable for large-scale objects such as buildings or vehicles, with ranges extending from a few centimeters to several meters.

3D scanning systems generally support several file formats for the output data. The most common formats include:

STL (stereolithography)

OBJ (Wavefront)

PLY (Polygon File Format)

ASC (ASCII Text Data)

The speed at which a scanner captures data varies. Faster scanning is essential for large-scale applications where time is critical. High-precision scanners typically offer speeds of 2-3 million points per second, but slower scans provide better accuracy in detailed modeling.

While high-precision 3D scanning offers numerous benefits, it is not without challenges. Below are some of the most common issues businesses face when using this technology.

Cause: Scanning complex geometries or highly reflective, transparent, or dark surfaces can lead to incomplete or missing data points.

Solution: To avoid this, use multi-angle scanning or specialized software that can fill in gaps in the data. Some systems also allow for post-scan correction to fill in missing areas.

Cause: Using low-resolution settings for scanning can lead to models that lack sufficient detail, especially for intricate or small objects.

Solution: Ensure that the resolution of the scanner is appropriate for the object being scanned. Always perform test scans to verify the detail level and adjust settings as needed.

Cause: When scanning an object from different angles, there is a risk of misalignment in the data, especially if the scanner isn't calibrated correctly or if the object moves between scans.

Solution: Utilize automatic alignment tools in reverse design software and ensure that the scanner is calibrated correctly before each scan. Reference points on the object can also help align scans more accurately.

Cause: High-precision 3D scanning and data processing can be resource-intensive, leading to slow performance or crashes, particularly on underpowered computers.

Solution: Use computers that meet or exceed the recommended hardware specifications for your 3D scanning software. Keep software up to date to address bugs and improve system performance.

Proper storage of your 3D scanning equipment is crucial to ensure its longevity and maintain its performance. The following guidelines will help ensure your equipment stays in optimal condition:

Temperature: Store 3D scanning devices in an environment with a stable temperature, ideally between 18°C to 25°C (64°F to 77°F). Extreme temperatures can affect the scanner's calibration and electronics.

Humidity: Humidity should be kept between 40% and 60%. High humidity levels can cause moisture buildup inside the scanner, leading to potential damage or malfunction.

Dust-Free Environment: Store the equipment in a clean, dry area to prevent dust and debris from entering the scanner’s internal components.

Protective Cases: When not in use, store the scanner in a protective case to shield it from accidental bumps, scratches, and dust accumulation.

Avoid Drops: Always handle 3D scanning equipment with care. If it is portable, use carrying cases with padding to protect against impact.

Cable Management: Ensure that cables and connections are neatly organized to prevent wear and tear or accidental disconnections.

The use of high-precision 3D scanning and reverse design technology offers significant advantages to businesses across a variety of industries. Below are some of the key benefits:

With high-precision scanning, businesses can ensure that their digital models closely match the physical objects they are replicating. This leads to better product designs, more accurate prototypes, and improved quality control in the manufacturing process.

By using 3D scanning, businesses can significantly reduce the time spent on the initial stages of product development. The ability to quickly capture and convert physical objects into digital models allows for faster design iterations and shorter product lifecycles.

Reducing the need for multiple physical prototypes can lower production costs. 3D scanning also eliminates errors that could occur during manual measurements, saving both time and money. The improved efficiency in data collection and model creation further contributes to cost savings.

3D scanning allows for easy modifications of scanned models, making it ideal for customizing products or iterating on existing designs. If changes are needed, the model can be adjusted digitally and re-manufactured without the need for new physical prototypes.

High-precision 3D scanning is used across a wide range of sectors, including:

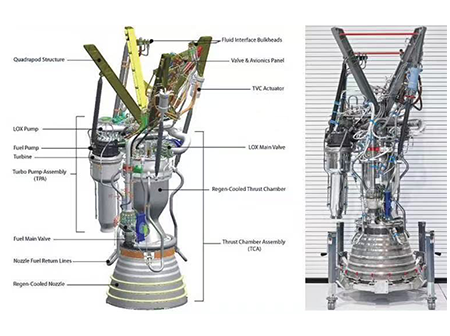

Aerospace: For creating detailed models of aircraft components and improving the design and testing process.

Automotive: For prototyping and reverse engineering car parts to improve design and performance.

Medical: For creating customized implants or prosthetics based on patient-specific data.

Manufacturing: For quality control, part replication, and tooling design.

High-precision 3D scanning data processing is a powerful tool that provides businesses with the ability to create accurate digital models from physical objects. By understanding the technical specifications, common issues, and storage conditions associated with this technology, businesses can better utilize these systems to improve product development, enhance quality control, and reduce costs.

The advantages of using 3D scanning for reverse engineering, prototyping, and manufacturing are numerous, ranging from increased accuracy and faster product development to greater flexibility and cost savings. With proper maintenance, storage, and troubleshooting, companies can maximize the potential of their 3D scanning systems, ensuring long-term success and innovation.

This website uses cookies to ensure you get the best experience on our website.